New Deburring Labo Opens: Focused on Advancement, Automation, Collaboration, and Solutions for Deburring Sugino Machine Co., Ltd. (Namerikawa City, Toyama Prefecture, President & CEO: Yoshiaki Sugino) and Sugino Corp. (Itasca, IL, President & COO: Don Reeder) are pleased to announce the opening of the “Deburring Labo at SUGINO” which has been established at the Kakegawa Plant (Kakegawa City, Shizuoka Prefecture). …

Meeting the Challenges of Machining with Free Cutting Steel

Free cutting steel has many advantages and is often used for its easy machinability. But these same malleability properties make roller burnishing and surface finishing difficult, as it can easily flake when pressure is applied. Below, we’ll dive in to learn how Sugino’s Superoll tools helped a customer manage the machining challenges of working with free cutting steel. Let’s start …

Burnishing Low Carbon Steel

A client came to us recently with a problem. They couldn’t reach the roundness specifications for their hydraulic valve with their usual burnishing tools. The pressure was causing deformation of the low-carbon steel part. Specification Roundness – .0003” Roughness – Ra 10 micro inch Competitor’s tool performance Roundness – .0008” Roughness – Ra 10 micro inch So we recommended using …

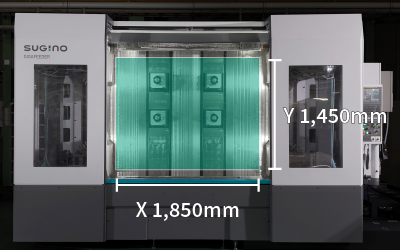

Axes in CNC Controlled Deburring and Cleaning

Missed last week’s piece on CNC Basics? This week in our CNC Deburring Series, we will take a deeper dive into axes. Axes play a role in CNC-controlled deburring programs in the same way they do in machining processes. When we pair decades of experience in handling and pressurizing water with the precise control of CNC operation, the end result …

CNC Basics for Deburring and Cleaning

This week, we’re taking a look at CNC controls in deburring and parts cleaning. What is CNC? And how it can be used with these technologies? Combining CNC controls with high-pressure water deburrs and cleans parts in one eco-friendly process, removing burrs and loose chips even in deep holes – all while leaving the part clean and free of debris. …

Mechanical Deburring Methods

In the past weeks, we have discussed types of burrs and the many methods of removal and today we’re taking a look at mechanical hard tool deburring. Mechanical deburring employs cutting, grinding, milling, or brushing tools to remove burrs through direct contact. It is ideal when burrs are simply too heavy or strong to remove with other methods. Mechanical deburring is …

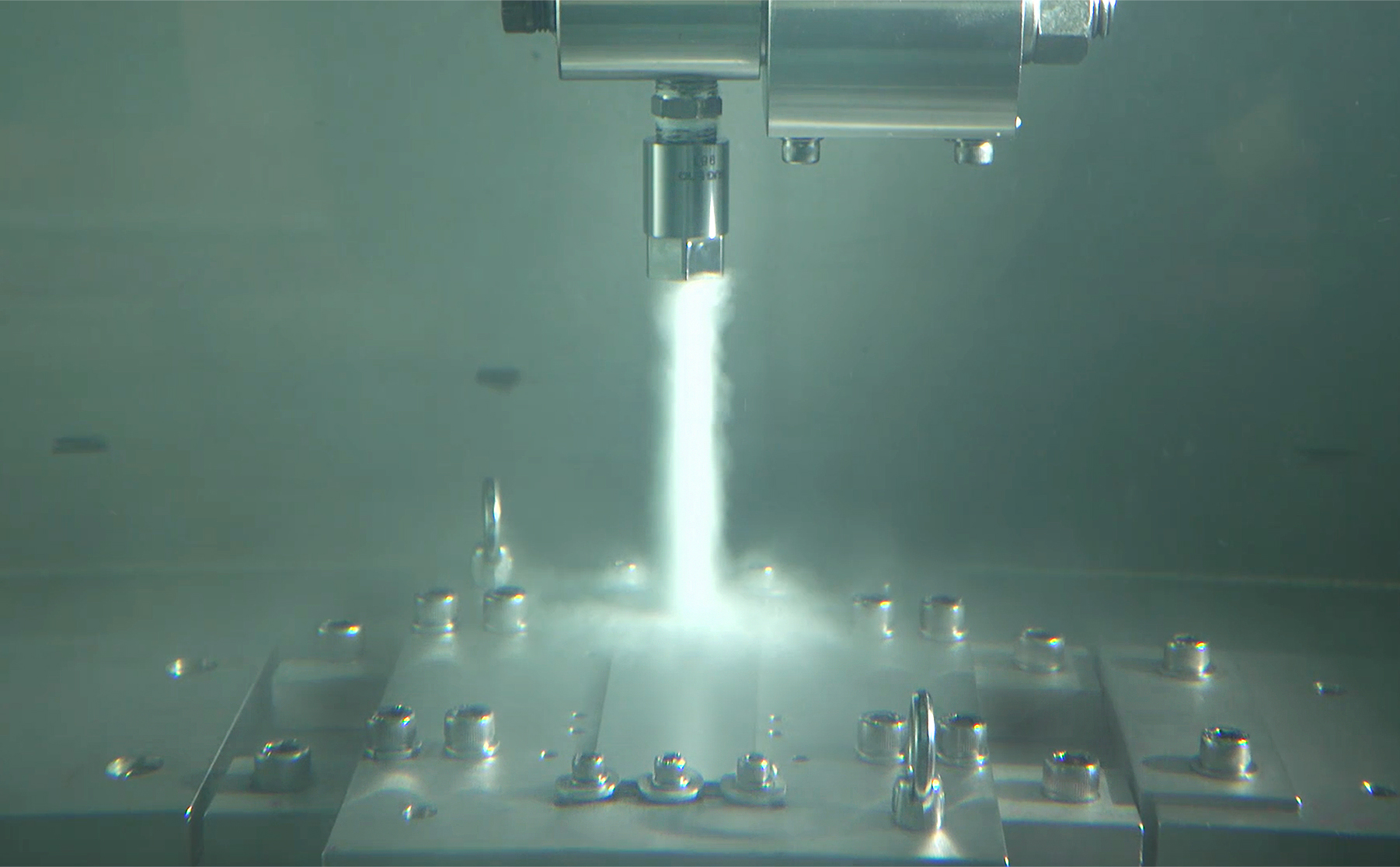

Benefits of High-Pressure Water Jet Deburring

As we have discussed previously, there are many ways to deburr. This week we’re taking a closer look at High-Pressure Water Jet Deburring. The first thing that bears mentioning is that CNC-controlled, high-pressure water jet deburring produces accurate, repeatable, and predictable results. For the right situation and parts, it’s an ideal solution to remove burrs. High-Pressure Water Jet Deburring is …

Common Deburring Methods

Last week we looked at the five classes that encompass most burrs. This week we are exploring the many common deburring methods that are frequently considered for removal. There are many options for deburring; manual vs. mechanical, with or without chemicals or solvents, explosive methods, grinding, tumbling, the list is extensive. The key is to determine the best method to …

Classification of Burrs

Last week we spent some time covering the identification of burrs. Why? Because classification of burrs can help you pinpoint the best removal processes and prevention methods. This week we look at the classes burrs fall into. Burrs come in many types, and they can then be categorized in several different ways. They can be sorted by machining process, machining …

- Page 1 of 2

- 1

- 2