Stir and Defoam Machine

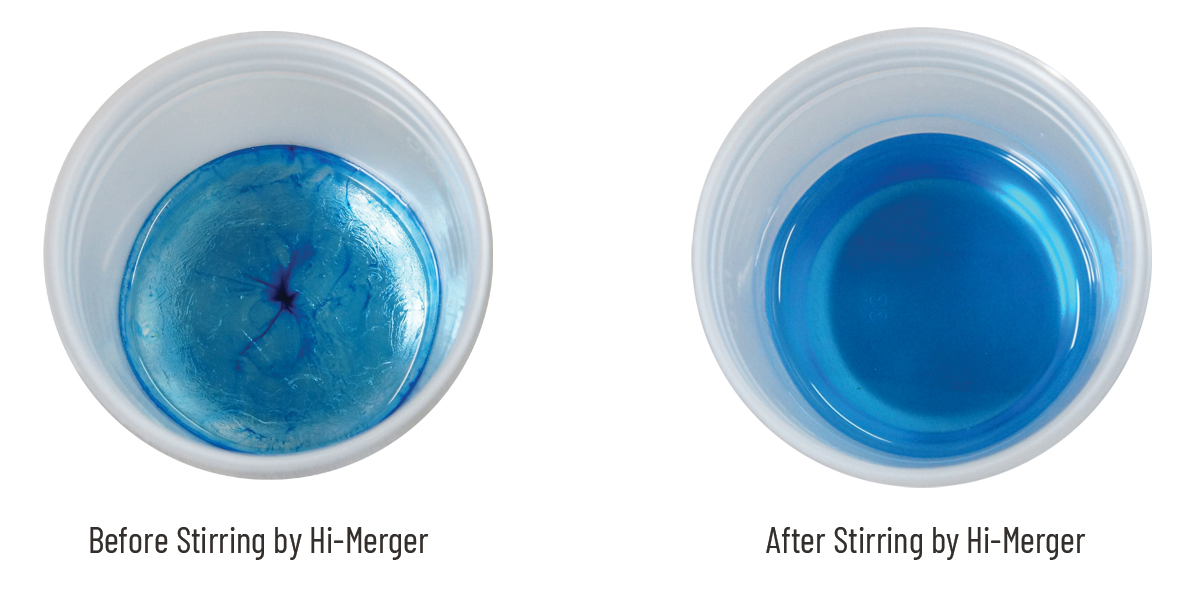

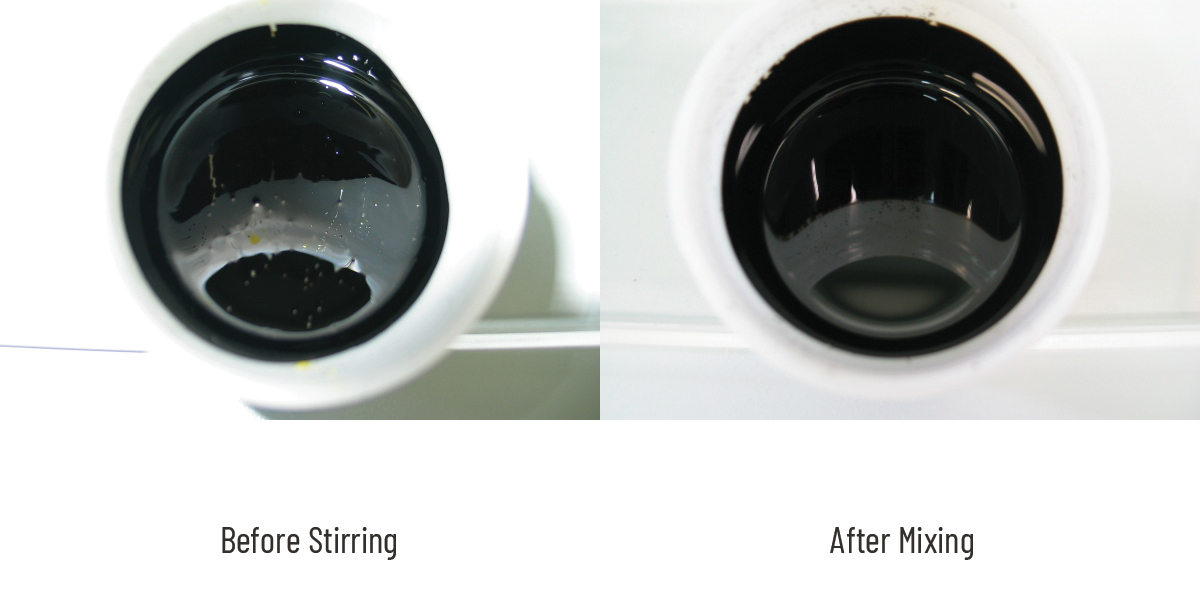

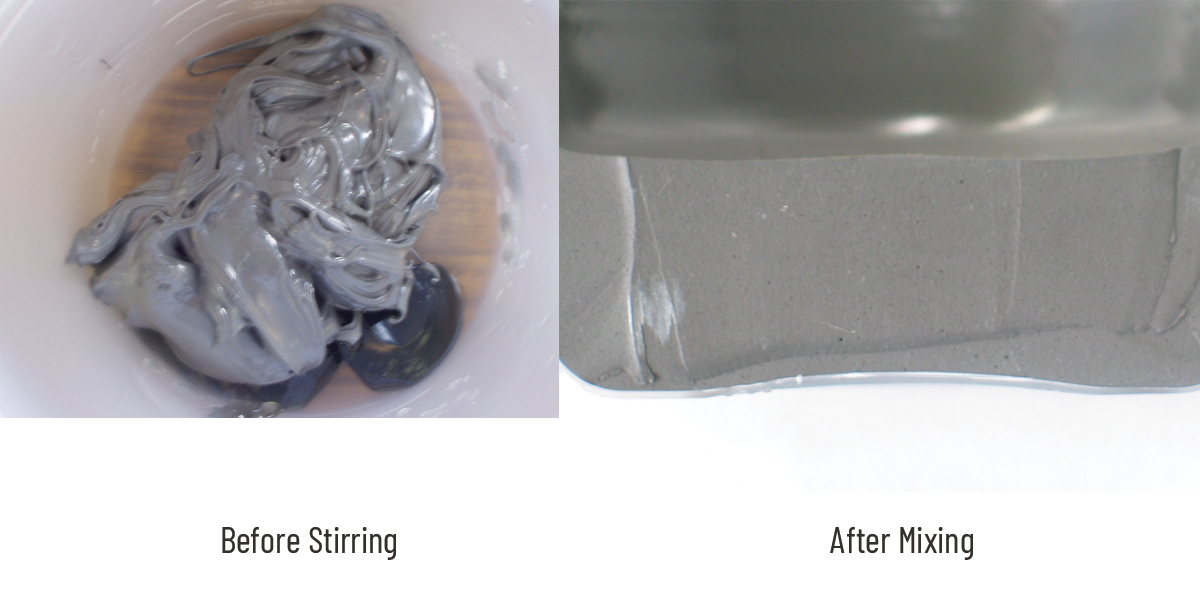

Mixing

Ideal for powders and liquids, or for combining different liquids to make a uniform paste and/or slurry.

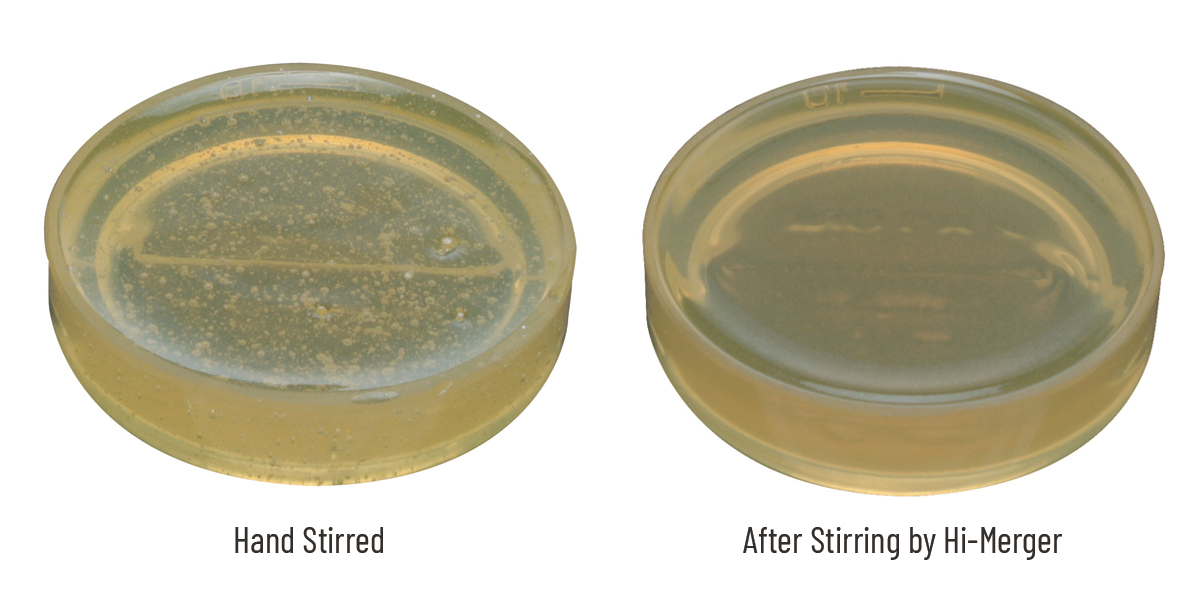

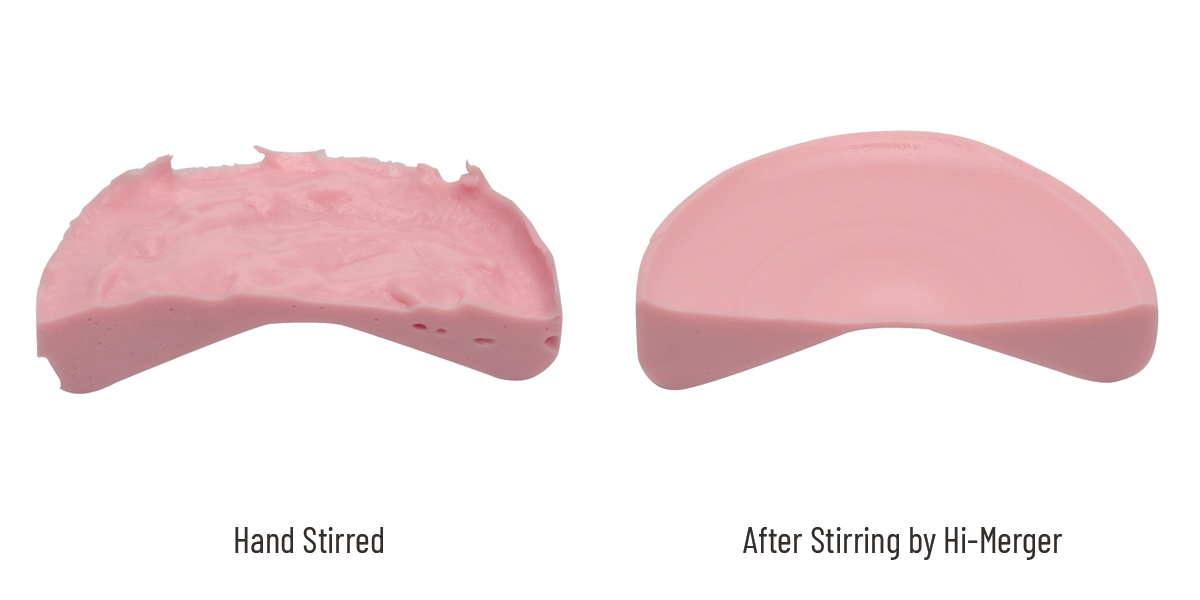

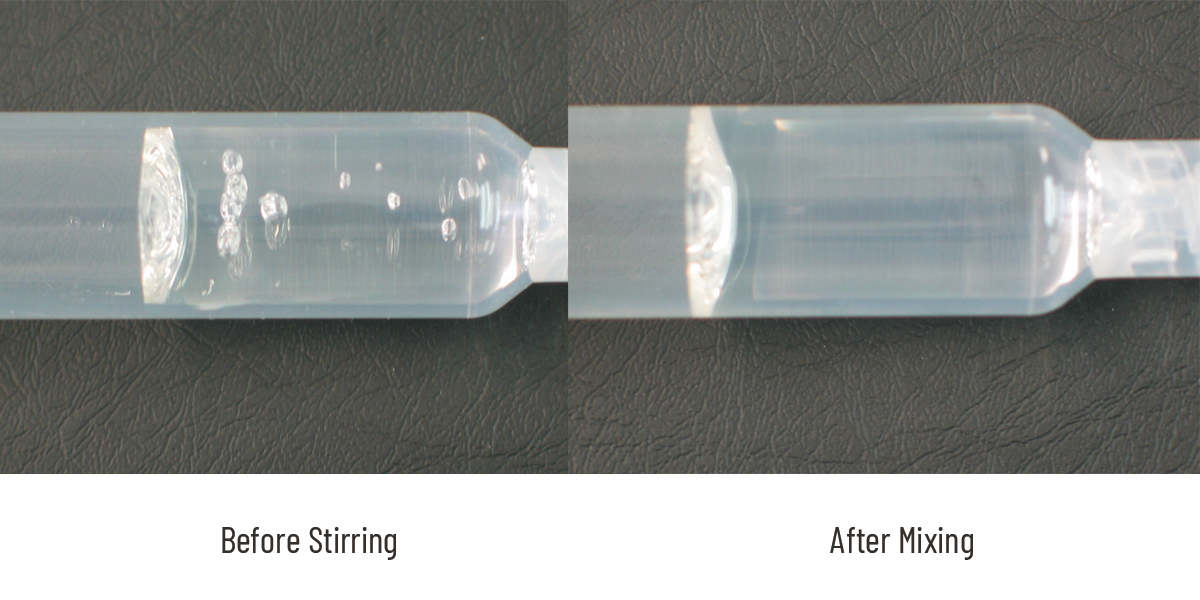

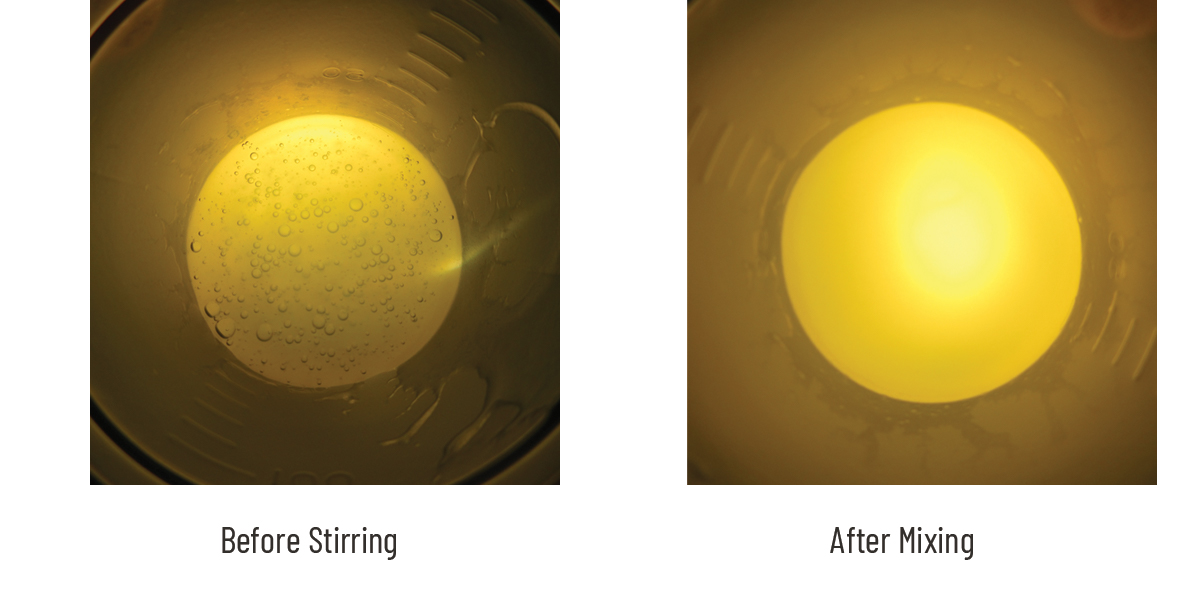

Defoaming

Efficiently and effectively removes bubbles in paste, slurry and liquid.

Degassing

Removes dissolved gas from liquid by using a vacuum pump.

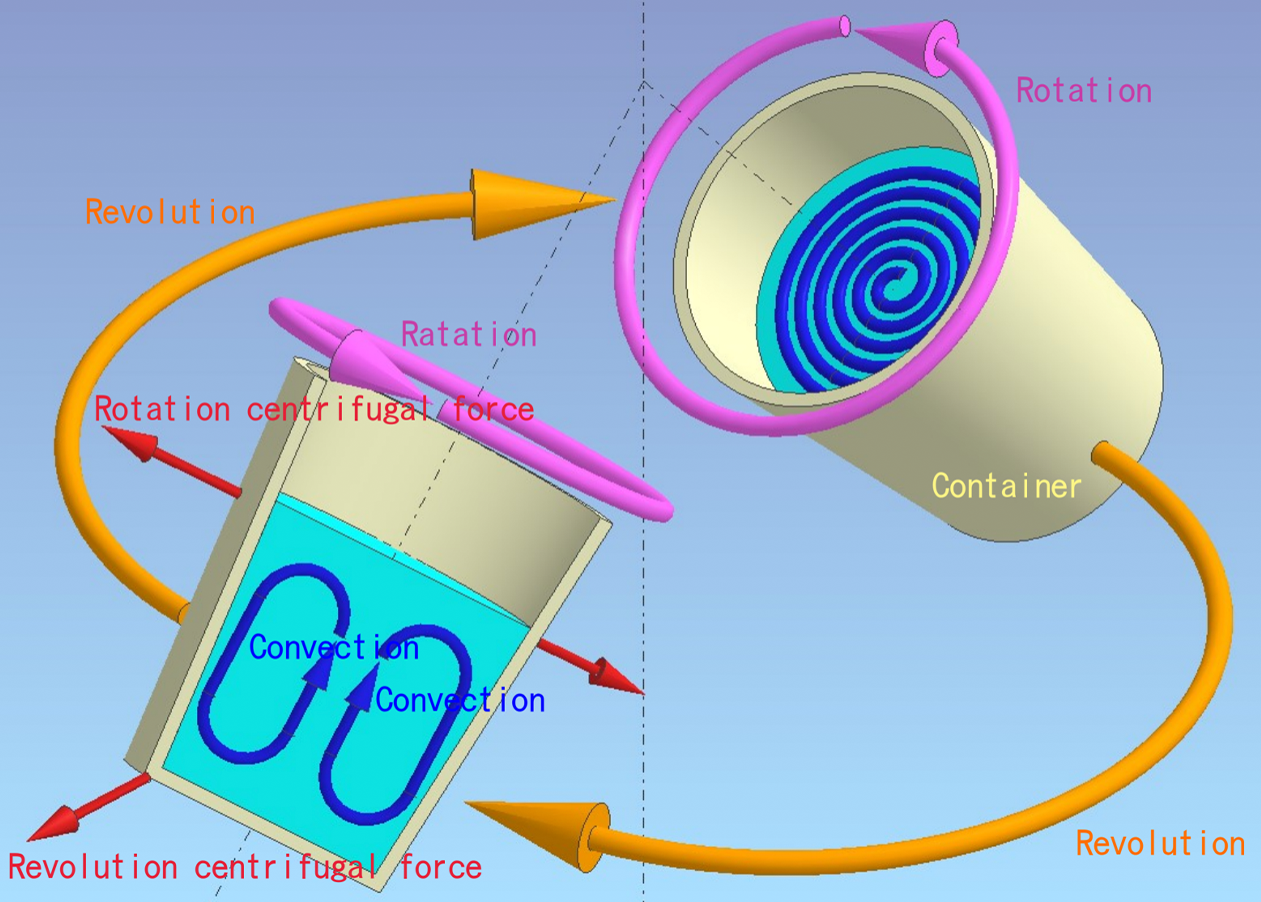

Rotation & Revolution

Utilizes rotation and revolution simultaneously at high-speed.

Hi-Merger pushes out the bubbles created during processing by using simultaneous rotation and revolution at high speed - generating convection flow.

Atmospheric pressure type sufficiently defoam, but to remove dissolved gas in your material, vacuum pressure is recommended.

With no rotor blade, Hi-Merger causes no direct damage to the materials, and no loss of materials during processing.

APPLICATIONS

RESIN, ADHESIVE, SEALING COMPOUND

- Epoxy resin, silicone resin, acrylic resin, urethane resin

- Sliding agent (SKC, Moglice, Turcite bond) varnish, gasket sealant gum

- Two-component adhesive, single-component adhesive, UV curing glue, adhesive for optical lens (Balsam etc.)

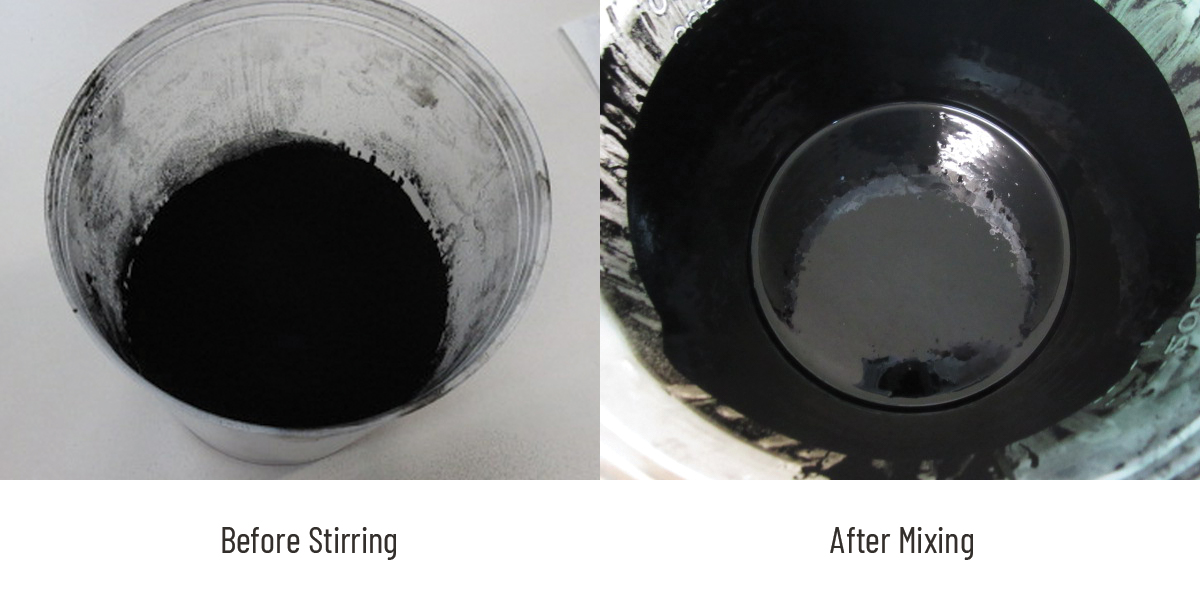

- Black-painting materials: Paint for optical elements, anti-reflection paint on the inner surface of the lens GT-7, etc.

ELECTRICAL MATERIALS

Solder paste, silver paste, conductivity, resistance-insulating paste, insulating varnish, encapsulant, encapsulant for LED sealant, secondary battery material

INK, PAINT, PIGMENTS

Printing inks, paint, toner

APPLICATIONS

COSMETICS

Lipstick, mascara, nail products, creams and emulsions, foundation

CHEMICAL MATERIALS, RESEARCH AND DEVELOPMENT (R & D)

Cellulose Nanofibers (CNF) material, Biomass nanofiber

MINERAL, LUBRICATING OILS

Abrasive grains, cement, lime, sintered material, grease

FOOD

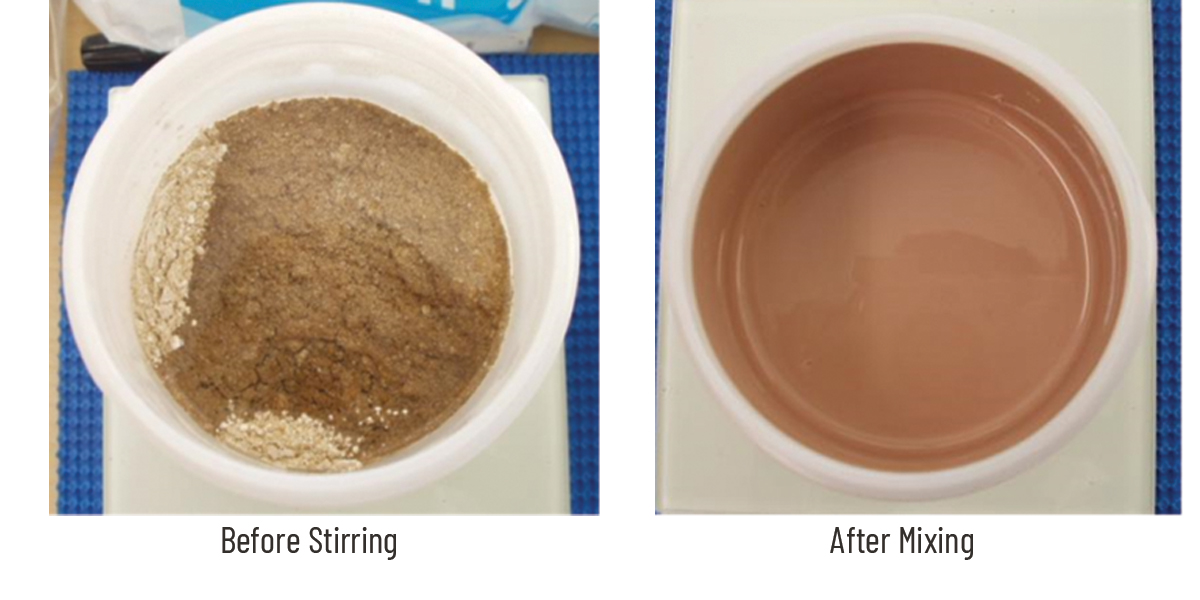

Syrup, starch, powder

MEDICAL AND DENTAL MATERIALS

Medical components, medical products, tinctures, ointments, dental materials including Alginic acid, dental mold materials

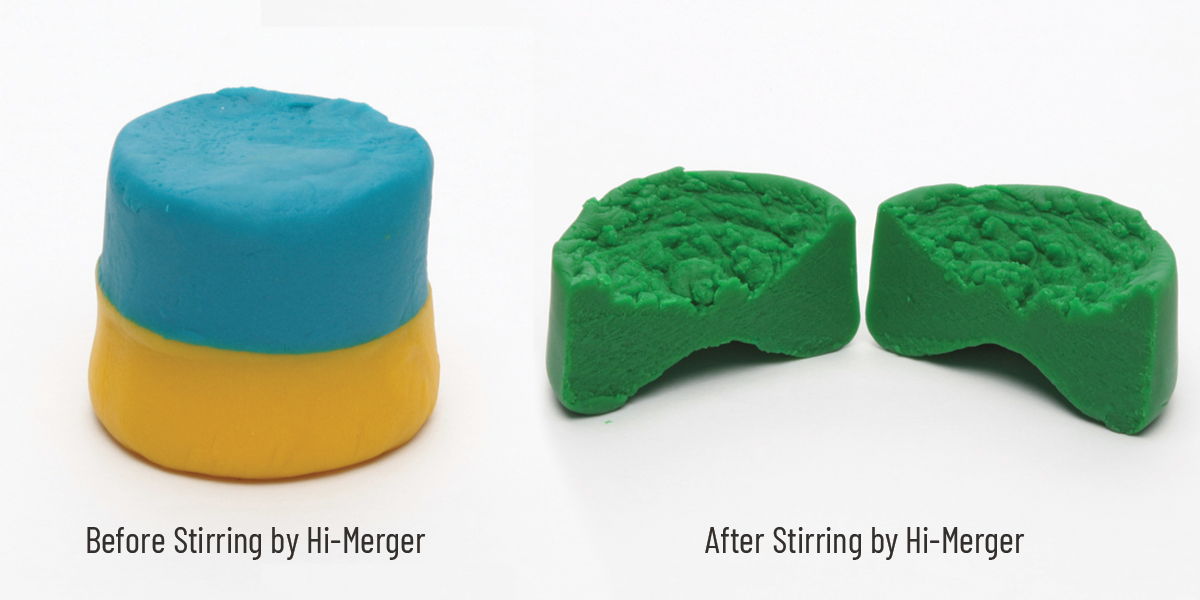

Material Examples

Clay

Epoxy Resin

Two-Component Adhesive

Algin Acid

Silicone

Black Painting Materials

Ultraviolet Cure Glue

Sealant

Insulating Paste

Varnish and Pigment

Foundation

Essence

Grease

Starch and Syrup

Compact model with auto-balance function

The HM-50SE is capable of processing up to 50ml in a compact, easy to handle size. This model is equipped with an auto-balance function - there's no need to adjust the weight of your materials to ensure balance. A desktop or benchtop unit, ideally suited for R and D applications.

Click to Zoom

Features

- Auto-balance function - no need to adjust weight of material

- For small amounts / quantities - ideally suited for R&D applications

- Desktop or benchtop type, space-saving, easy to carry and place

- 1 axis control - speed ratio between rotation and revolution is fixed, easy-to-control settings

Specifications

| Capacity | 50ml x 1 |

|---|---|

| Type | Bench mount |

| Additional function | Auto-balance |

| Time setting | 1seconds ~ 99minutes59seconds |

| Controlled axis | 1-axis |

| Revolution speed | 200 ~ 2,000min-1 |

| Rotation speed | 100% of revolution |

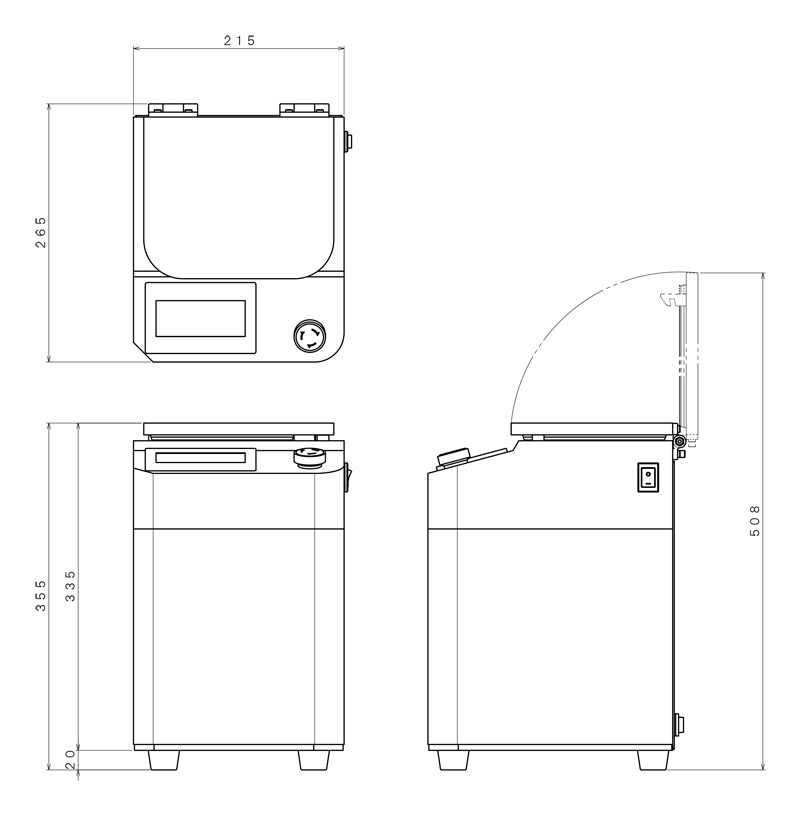

| Dimensions | Width215 x Depth265 x Height355mm |

| Weight | 20kg |

| Usage environment | 5 ~ 35˚C 35 ~ 85%RH(No condensation) |

| Power supply | AC100 ~ 115V 50/60Hz Max.0.4kVA |

Dimensions

Available Options

Assorted containers

Adaptor for containers

.

.