Total Chemical Reactor Cleaning Systems

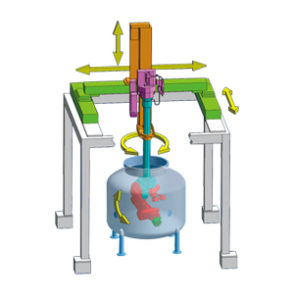

Sugino Reactor Cleaning Systems are designed to safely and effectively peel and clean scale stuck to the inside of polymerization tanks, reactors, and storage tanks by using high-pressure water. We design and manufacture all the relevant items for the system (high-pressure pump, cleaning device, nozzle, and controller).

The crux of the Reactor Cleaning System

is the rotating/revolving precision cleaning nozzle.

The "3D Nozzle" is a self-rotating nozzle unit used for cleaning polymerization tanks, reactors, spray dryers, and various other tanks. The cleaning nozzle rotates and revolves due to the reactive force of the high-pressure water spray, thoroughly cleaning the inside of tanks.

Uniform cleaning

When compared to conventional methods of cleaning, the precision of the 3D Nozzle is about twice as accurate, making high-quality, clean washing possible. The rotation of the nozzle is controlled by a magnetic braking mechanism. This provides an even rotation speed and enables stable cleaning, since it is not influenced by atmospheric temperature or clogging.

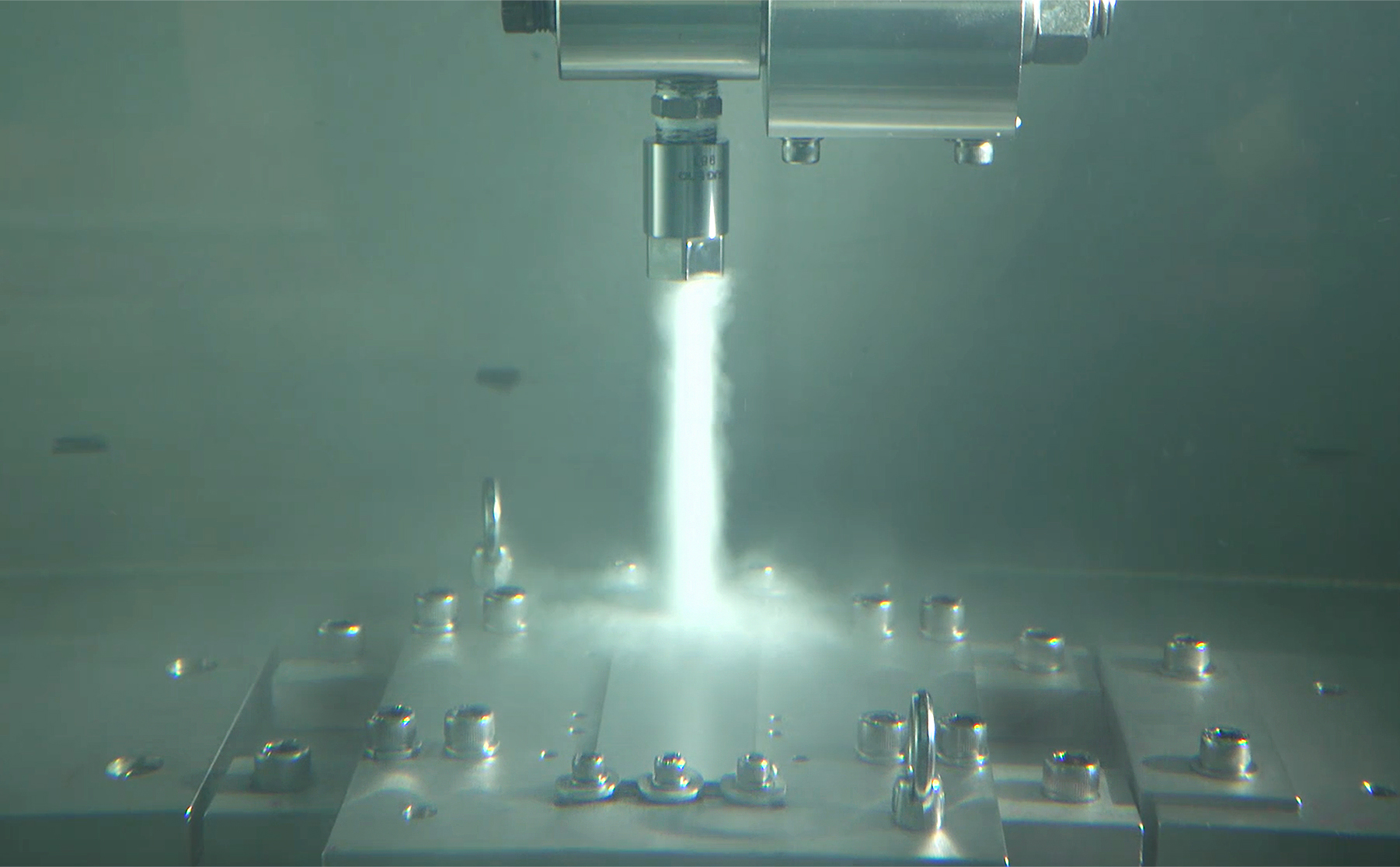

Improved cleaning

An improved convergence of high-pressure water is achieved by utilizing a special nozzle uniquely developed by Sugino. This improves cleaning significantly since the loss in impact energy of the high-pressure water is minimized.

Model number |

Pressure |

Flow rate |

Nozzle rotation speed |

Dimensions |

Connection screws |

Weight |

N |

||||||

MPa |

L/min |

min-1 |

mm |

Screw size |

kg |

|

| JRN-080PG | 10-30 | 50-80 | 14-40 Stepless adjustment |

238 x 92 | Rc3/4 | 6.5 |

| JRN-200PGS | 10-45 | 80-200 | 250 x 8 | 7.0 | ||

| JRN-200PG | 80-200 | 248 x 102 | 7.0 | |||

| JRN-400PG | 200-400 | 307 x 132 | Rc1 1/4 | 13.0 | ||

| JRN-150HPG | 45-70 | 80-150 | 270 x 102 | Rc 3/4 | 8.0 | |

| JRN-130HHPG | 50-100 | 60-130 | 280 x 102 | 10.0 | ||

| JRN-100PGS | 10-45 | 50-100 | 18-40 | 276 × 80 | 8.0 | |

| Stepless adjustment |

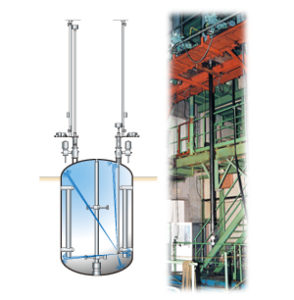

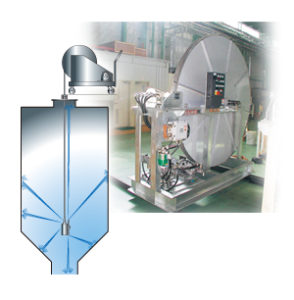

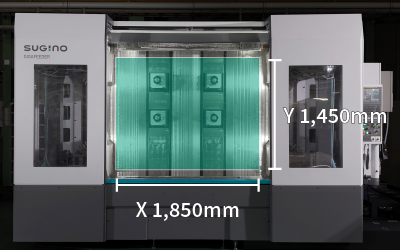

Stationary High-Pressure Water Cleaning Equipment for the Inside of Tanks

Makes small, compact and highly accurate cleaning possible!

The "Jet Lancer" is a cleaning equipment in which the overall height of the compact lance is lowered by adopting a multilevel screw format in the lance lifting mechanism.

Features

- Small and compact By lowering the overall height of the cleaning equipment, it can easily be housed in an existing reactor with limited ceiling height.

- Precision cleaning is possible As the cleaning point can be installed in any desired location, it makes more precise and accurate cleaning possible in a shorter time.

At the same time, this helps to save water used for cleaning. - Can be attached to 6B small manholes By fixing original Sugino cleaning attachments, it can also be installed in the reactor of 6B small manholes.

Specifications

| Model number | Pressure | Flow rate | Elevating stroke | Elevating speed | Dimensions | Weight |

| MPa | L/min | mm | m/min | mm | kg | |

| JTL-1955WL | 45 | 50 - 200 | 5,500 | 1.5 | W 200 × D 350 × H 4,000 |

500 |

Note: Other jet lancers with specifications not mentioned above are also available. Please contact the nearest Sugino sales office.

Application Examples

-

Polymer tank

- Reaction tank

- Various other types of tanks etc.

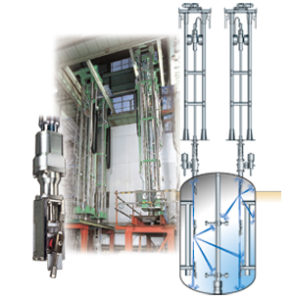

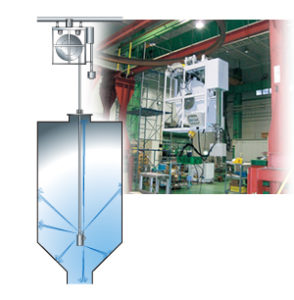

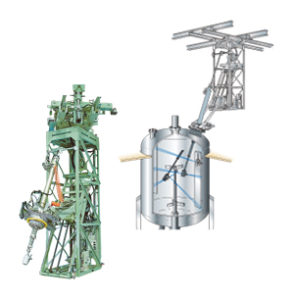

Movable Type

Movable Type High-Pressure Water Cleaning Equipment for the Inside of Tanks

Automatic control of lance transportation and washing.

"Automatic Slide Lance" automatically controls lance transportation and reactor washing. Operation can be performed with the a push of a button. It is excellent in safety and workability, and provides significant labor-saving. The "Automatic Slide Lance" has four types - suspension moving, floor moving, hoist, and manual transport types - depending on the transportation method.

| Suspension Moving Type | Floor Rotation Type |

|

|

Application Examples

-

Polymerization tank

-

Reactor tank

-

Fermentation tank, etc.

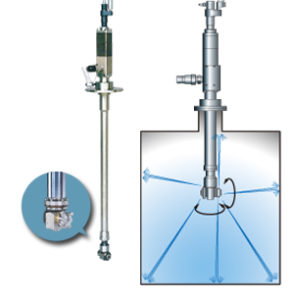

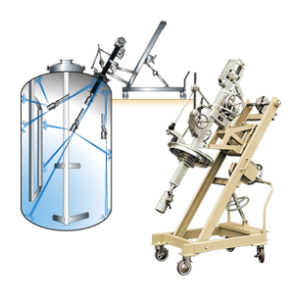

Special Application Cleaning Equipment

Stationary High-Pressure Water Cleaning Equipment for the Inside of Containers

Total cleaning of the inside of containers.

The "Container Cleaning Equipment" is a device that completely cleans the inside of a container by mounting a 3D nozzle in the center of the container.

Automatic cleaning is possible by setting the container in a fixed position.

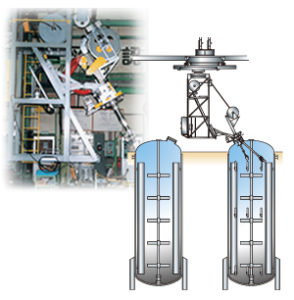

High Pressure Water Cleaning Unit

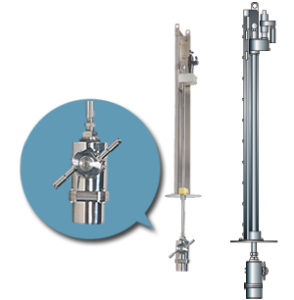

Automatic Rotating/Revolving, High-Pressure Water Cleaning Nozzle Unit for the Inside of Tanks

Rotating/revolving precision cleaning nozzle!

The "3D Nozzle" is a self-rotating nozzle unit used for cleaning polymerization tanks, reactors, spray dryers, and various other tanks.

The cleaning nozzle rotates and revolves due to the reactive force of the high-pressure water spray, thoroughly cleaning the inside of tanks.

Features

- Uniform cleaning

When compared to conventional methods of cleaning, the precision of the 3D Nozzle is about twice as accurate, making high-quality and clean washing possible. The rotation of the nozzle is controlled by a magnetic braking mechanism.

This provides the nozzle with an even rotation speed and enables stable cleaning since it is not influenced by atmospheric temperature or clogging. - Improved cleaning

An improved convergence of high-pressure water is achieved by utilizing a special nozzle uniquely developed by Sugino. This improves cleaning significantly since the loss in impact energy of the high-pressure water is minimized.

Specifications

| Model number | Pressure | Flow rate | Nozzle rotation speed | Dimensions | Connection screws | Weight |

| N | ||||||

| MPa | L/min | min-1 | mm | Screw size | kg | |

| JRN-080PG | 10-30 | 50-80 | 14-40 Stepless adjustment |

238×92 | Rc3/4 | 6.5 |

| JRN-200PGS | 10-45 | 80-200 | 250 × 80 | 7.0 | ||

| JRN-200PG | 80-200 | 248 × 102 | 7.0 | |||

| JRN-400PG | 200-400 | 307 × 132 | Rc1 1/4 | 13.0 | ||

| JRN-150HPG | 45-70 | 80-150 | 270 × 102 | Rc3/4 | 8.0 | |

| JRN-130HHPG | 50-100 | 60-130 | 280 × 102 | 10.0 | ||

| JRN-100PGS | 10-45 | 50-100 | 18-40 Stepless adjustment |

276 × 80 | 8.0 |

Note 1. The JRN-100PGS is a slim type of 3D Nozzle that can pass through tank holes of diameter 150.

2. The overall length of the nozzle (B) may change depending on cleaning factors such as the dimensions of the reactor, diameter of tank hole, etc.