When considering your production processes and the parts you are working with, you’re likely going to consider each aspect of the systems you’re reviewing carefully. There’s not only the technology inside the “box” but the accessory components and options that take a system from basic, to finely-tuned to your needs. It can also affect your process downstream. Get Familiar with …

Mechanical Deburring Methods

In the past weeks, we have discussed types of burrs and the many methods of removal and today we’re taking a look at mechanical hard tool deburring. Mechanical deburring employs cutting, grinding, milling, or brushing tools to remove burrs through direct contact. It is ideal when burrs are simply too heavy or strong to remove with other methods. Mechanical deburring is …

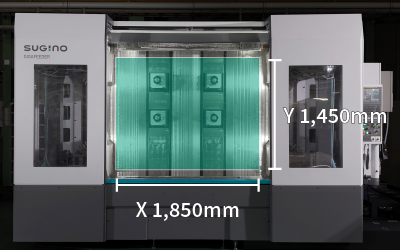

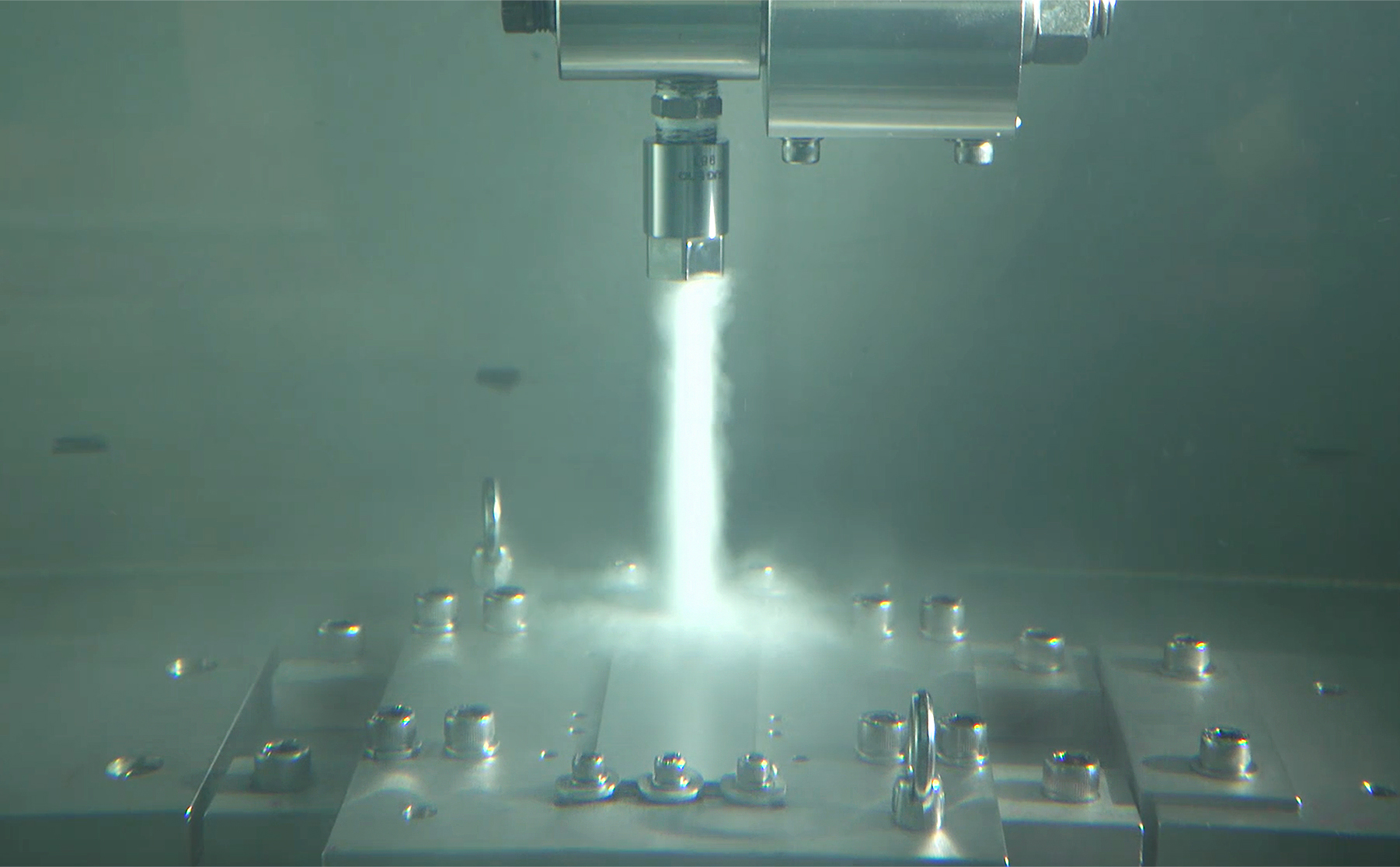

Benefits of High-Pressure Water Jet Deburring

As we have discussed previously, there are many ways to deburr. This week we’re taking a closer look at High-Pressure Water Jet Deburring. The first thing that bears mentioning is that CNC-controlled, high-pressure water jet deburring produces accurate, repeatable, and predictable results. For the right situation and parts, it’s an ideal solution to remove burrs. High-Pressure Water Jet Deburring is …

Common Deburring Methods

Last week we looked at the five classes that encompass most burrs. This week we are exploring the many common deburring methods that are frequently considered for removal. There are many options for deburring; manual vs. mechanical, with or without chemicals or solvents, explosive methods, grinding, tumbling, the list is extensive. The key is to determine the best method to …

Classification of Burrs

Last week we spent some time covering the identification of burrs. Why? Because classification of burrs can help you pinpoint the best removal processes and prevention methods. This week we look at the classes burrs fall into. Burrs come in many types, and they can then be categorized in several different ways. They can be sorted by machining process, machining …

Types of Burrs by Machining Process

Burrs are not “one size fits all.” The types of burrs vary with machining processes and methods – and they come in just as many different types. Just joining us? Take a look at last week’s Deburring 101: Reasons Deburring is Crucial Identifying the type of burrs you are dealing with allows you to address not only the removal process, …

Why Deburr

Reasons Deburring is Crucial Last week we established that burrs can cause problems to your workforce, your production efficiency, your machinery, and your final product. Let’s look more deeply at why it’s such an important topic. Workplace Safety: We have all heard about safety first, but that’s because it is the cornerstone of the workplace. Injuries not only hurt the …

Burr Problems – Deburring 101

We’re back this week with an installment of our weekly series, Deburring 101. Let’s kick it off with some deburring basics. What is a burr? Merriam Webster defines a burr as “a thin ridge or area of roughness produced in cutting or shaping metal.” Wikipedia says, “A burr is a raised edge or small piece of material that remains attached …