How to Choose the Best Fit for Precision Deburring and Productivity

Every machined part ends up with burrs. These unwanted metal protrusions can affect function, quality, and safety. But not all deburring methods are created equal, and the choice you make affects throughput, consistency, labor cost, and your ability to scale.

In this guide, we break down the most common methods from manual finishing to advanced automated techniques, and help you see where machine-driven automation delivers repeatable precision with less labor risk and greater throughput.

Manual vs. Machine-Based Methods

Manual deburring — whether with files, hand wheels, or bench tools — delivers variable results because it depends on individual skill and judgment. Even the most experienced operators deliver inconsistent finishes on different shifts or parts.

Modern manufacturing demands repeatability, throughput, and predictable quality. Attributes that are difficult to achieve through hand finishing. That’s where machine-based and automated approaches come in: they turn deburring into a controlled, measurable process with less reliance on operator skill.

A Look at Deburring Methods

Thermal Deburring

Fuel gas and oxygen are combusted under pressure. The resulting explosion incinerates the burr into oxidized powder.

Chemical Deburring

Micro-burrs are dissolved using a phosphoric acid-based or sulfuric/fluorine-based solution.

Mechanical Deburring

Cutting, grinding, milling, or brushing tools remove burrs through direct contact.

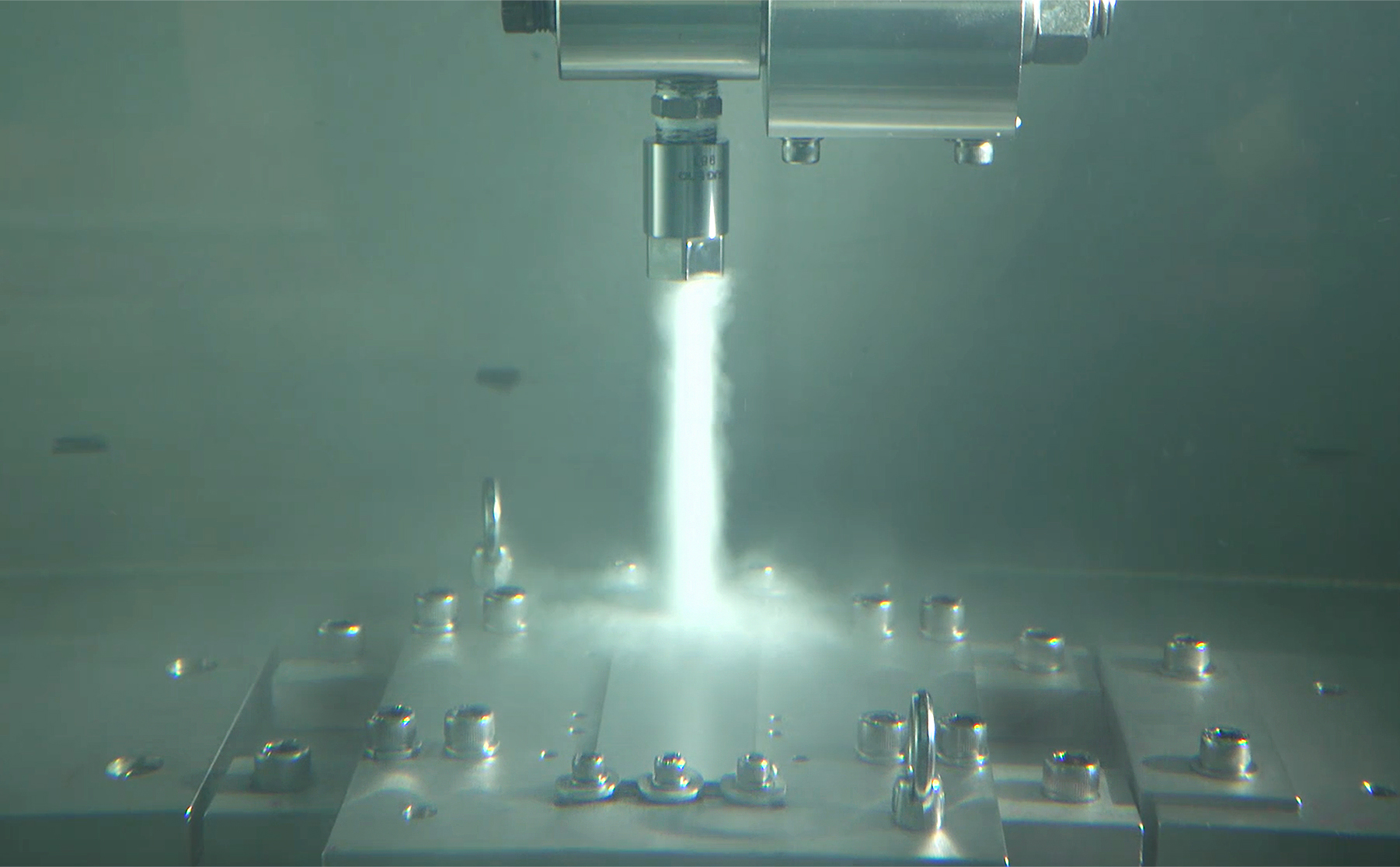

Water Jet Deburring

Water-jet deburring offers a high level of precision and repeatability thanks to CNC control. This eco-friendly process uses high-pressure water to remove loose burrs and chips even in deep holes – while leaving parts clean and free of debris.

Rotary Tool

Deburrs by a rotating tool with a special protruded edge. This can be made more efficient by mounting on a machining center or CNC lathe.

Belt Polishing

A loop of flexible abrasive paper (a belt) is driven by a machine to remove burrs. Large burrs can be removed efficiently, but burrs inside the workpiece or within holes are not accessible. This method can also result in secondary burr formation.

Electrochemical Deburring

Barrel Polishing

The part to be deburred is tumbled within a rotating barrel. This can run with or without water and with or without an added abrasive medium.

Brush Polishing

Brush polishing employs various-shaped brushes (wheel, roll, cup, spiral, etc.) to remove burrs. These can be mounted on a machining center or CNC lathe.

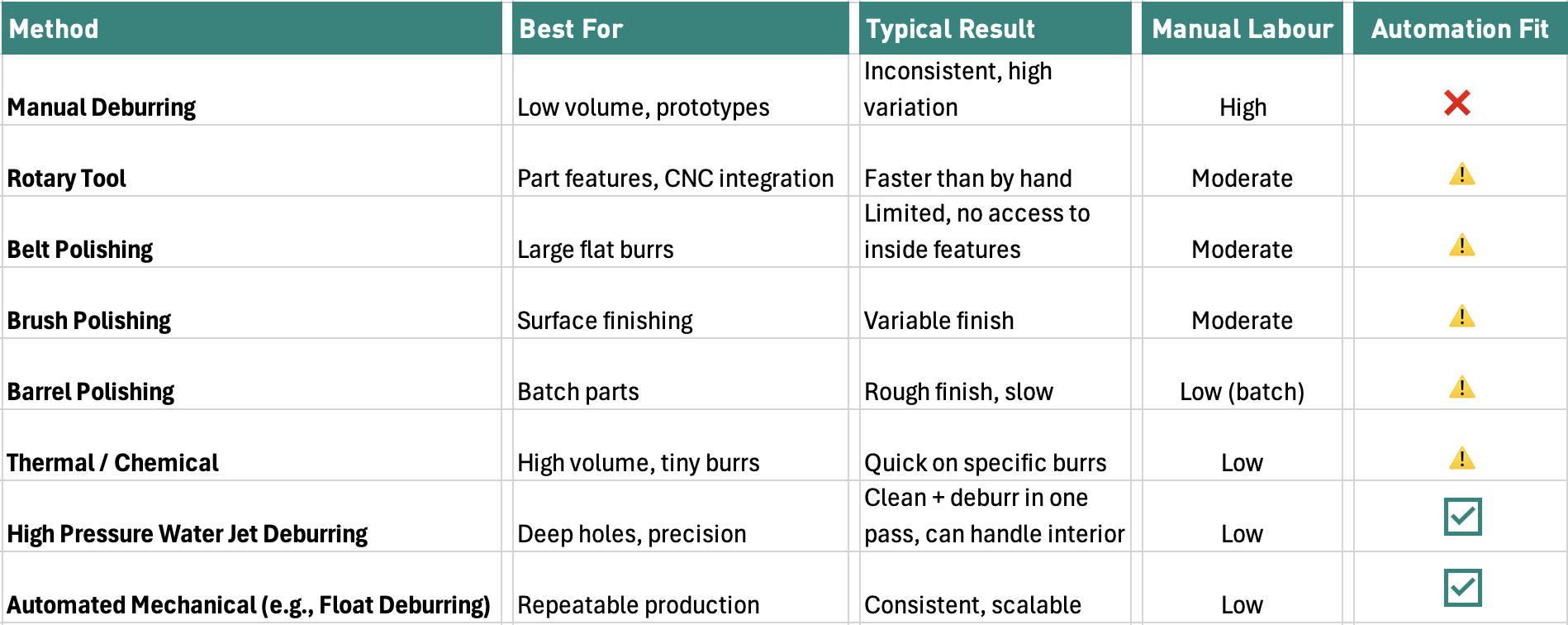

Breaking it All Down

Consider the pros and cons of these methods to determine how they might fit your needs:

Water Jet Deburring: Deburr + Clean in One Pass

High-pressure water jet systems remove burrs by using CNC control to direct focused water streams, delivering high precision, deep access, and simultaneous cleaning both outside, and in internal cavities and deep holes. This is especially useful when burrs are formed during machining and you want to consolidate processes.

When to consider it:

- If you work with complex geometries

- If you need to access deep internal features

- You want to deburr and clean in one cycle

- You are focused on an eco-friendly, renewable method

Float Deburring

Float deburring is an automation method that allows you to deburr in a machining center, with a robot, or in a dedicated deburring cell. It prevents burrs from being left behind and workpieces from being over-shaved by aligning the tool to the shape of the piece at a constant pressure.

When to consider it:

- Great for complicated workpiece shapes

- Can deburr edges and along surfaces, like parting lines from die casting

- You want to consistency across batches

Barrel, Thermal, and Chemical Methods: High Volume, Limited Precision

-

Barrel polishing tumbles parts but is often slow and limited in precision

-

Thermal deburring incinerates small burrs quickly but is best for uniform burr sizes.

-

Chemical deburring dissolves micro burrs but requires handling of acids and post-cleaning steps

Rotary, Brush, or Mechanized Tools

Rotary deburring tools and brush polishing automate a hand tool approach by mounting deburring bits or brushes in CNC machines. These are a step up from purely manual but still tied to operator setup and path programming and you may still struggle with high variation in workloads.

Some limitations to consider:

- Accessing burrs inside intersecting holes is not generally possible

- Consistency will vary from run to run

Where Automation Wins

Modern manufacturing increasingly shifts deburring into automated cells or integrated CNC workflows because:

- It reduces operator dependency and variability

- It improves throughput and cycle predictability

- It lowers secondary handling and rework

- It helps manage labor shortages and safety risks

Consider automating with a method that includes a self-compensating float mechanisms for adaptive compliance without constant human adjustment.

Not sure which methods fits your parts?

Final Thoughts: What to Consider When Choosing a Deburring Process

Is consistency more important than speed?

→ Machine automation beats hand or brush methods

Is manual deburring tying up valuable skilled labor, or simply costing too much?

→ Automate with a robot or dedicated machine

Is burr access difficult (internal, cross holes)?

→ Consider Water Jet Deburring to access the interior passages of workpieces

Are part volumes increasing?

→ Plan for automation now to avoid bottlenecks

Are deburring challenges limiting your ability to run unattended?

→ If lights‑out machining is your goal, deburring must be automated. Otherwise, it becomes a bottleneck requiring human intervention.

Are quality issues showing up downstream?

→ Consistent deburring reduces inspection issues or rework later