JCC 603 Robo

Variable Ultra-High Pressure CNC Robotic-Hand Type Washing Machine

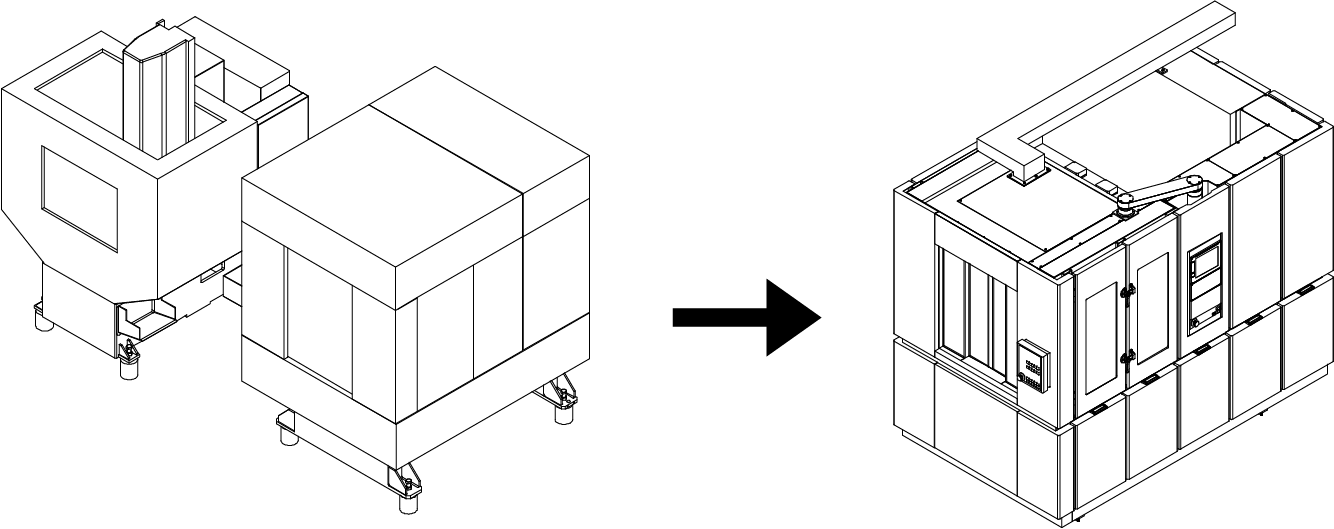

One Multi-tasking Machine

A highly efficient and precise washing machine that is capable of transferring, washing, and drying — all within a single machine. The use of a highly rigid robotic hand helps to reduce cycle time and decrease installation space. The world’s first MAX 245 MPa ultrahigh-pressure water jet enables deburring of steel materials that had previously been difficult to

clean up.

Features

Deburring with up to 245 MPa (35,500 PSI) High Pressure Water Jet

Mach 2 water jet cleans and deburrs with unparalleled precision.

Newly Developed Drive Shaft Patent Pending

The use of a new 2-axes joint developed to make targeting small workpieces easier, combined with XYZ 3-axes high-speed and high positioning accuracy, allows flexible and efficient hole and edge targeting.

Built-In Robotic Hand Changer

Deburring Applications

Deburring around cross-holes in cast iron and stainless steel parts, removal of tough edge burrs due to milling, and removal of oxidation scale after hardening.

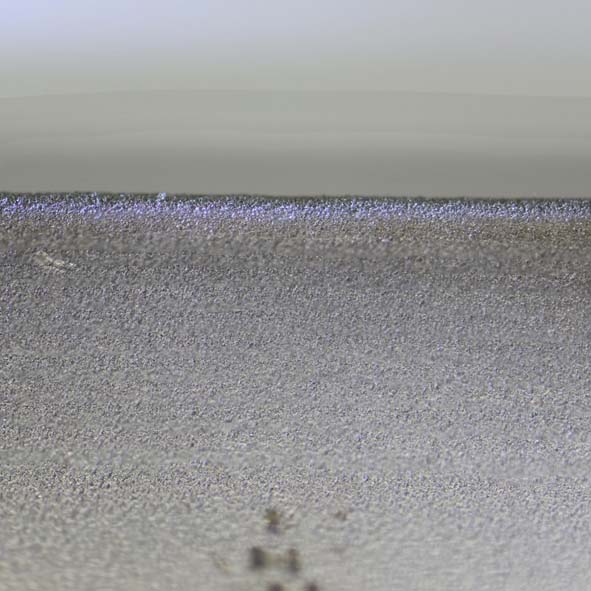

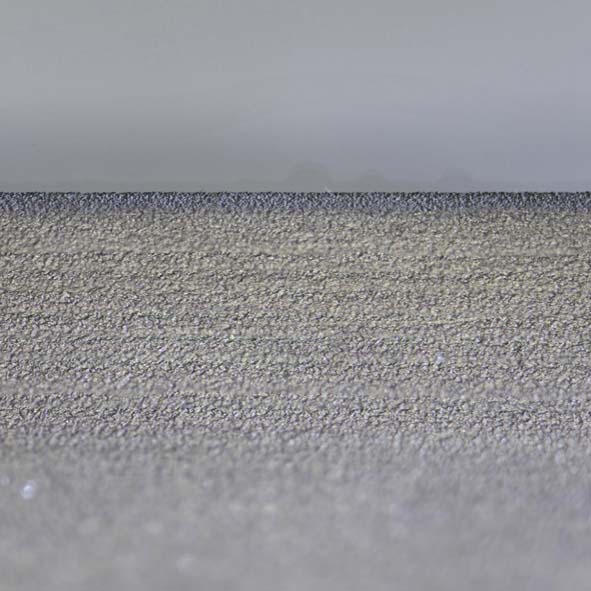

Stainless Steel

Before Deburring

After Deburring at 50 MPa (7,250 PSI)

After Deburring at 120 MPa (17,400 PSI)

After Deburring at 245 MPa (35,500 PSI)

Steel

Stainless Steel

Titanium

Inconel

Let us help you find the right solution for your application or production needs.

Applicable Work

Assembly components such as common rail, brakes, engine and transmission components,

hydraulic manifold, and other parts that require precision deburring.

Main Specifications

| Ultrahigh-pressure Washing Specifications | MAX 245 MPa x 4 L/min |

| Rinse Washing Specifications | 0.8 MPa x 100 L/min |

| Shaft Configuration (Stroke) | X-axis 650 Y-axis 500 Z-axis 500 mm A-axis ±90° C-axis 360° |

| Positioning Accuracy | 0.08 mm |

| Machine Dimensions | W 1,600 x L 2,660 x H 2,250 mm |

| Tank Station Dimensions | W 1,600 x L 2,800 x H 2,250 mm |

| Control Type | 3 direct axes + 2-axes joint CNC control |

| Waterproof Specifications | Fully-waterproof (electronic components completely separated from environment with water spray) |