Barriquan Robotic Mechanical Deburring Machine

Completely Automated.

The Sugino Barriquan™ Robotic Deburring Machine is an automated cell which features dual Barriquan high-speed spindles on an end-of-arm KUKA robot, designed to replace manual deburring in your factory.

In addition to the 6-axis robot, there is a rotary positioning table to give full 7-axis capabilities for deburring the most complex of parts.

The Barriquan Robot Deburring Cell also features the KUKA smartPA™ controller, stainless steel constructed framework, Lexan windows, a sliding front door assembly with safety switches, a removable chip tray, and forklift pockets for easy transport.

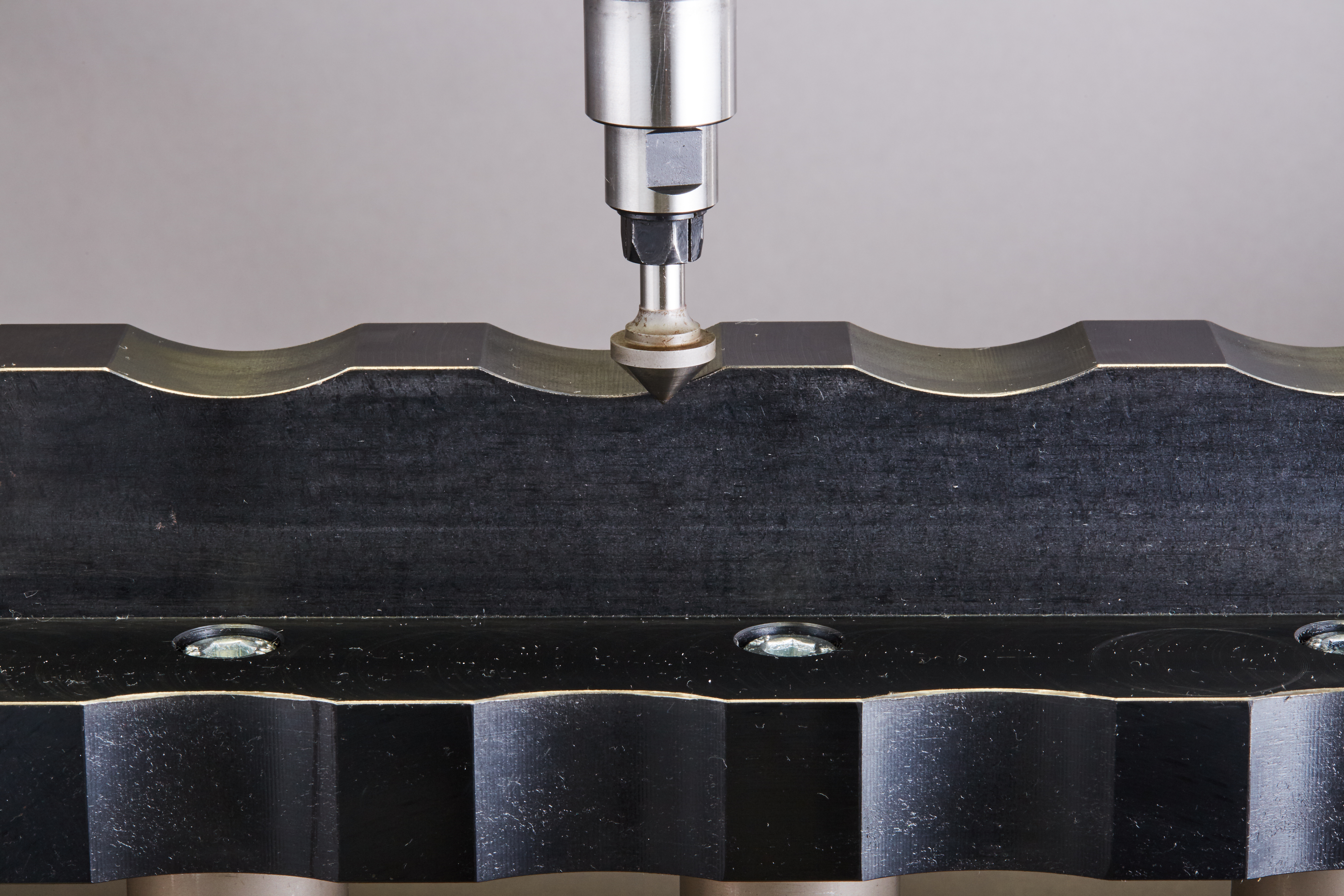

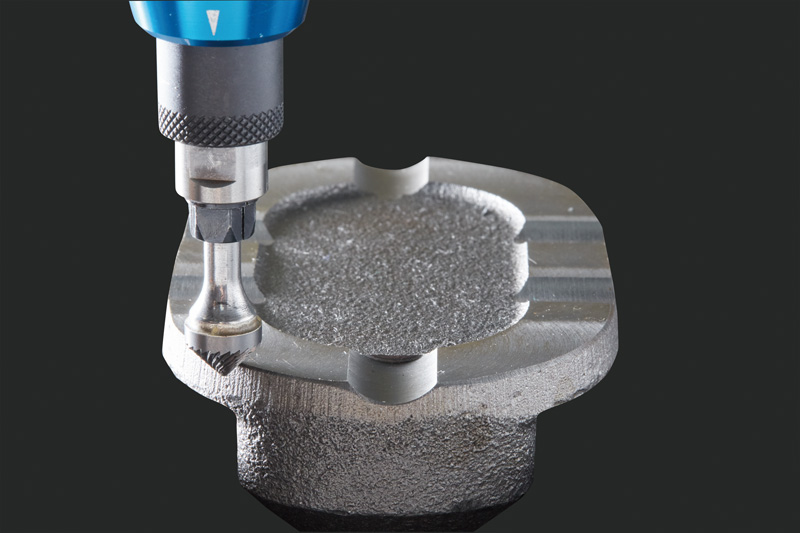

Self compensating contour deburring.

The "Barriquan" is a tool holder with a built-in floating mechanism. It keeps tools at a constant pressure against workpieces to allow profiling. Downforce pressure can be easily adjusted to meet burr requirements.

Learn more about Barriquan Tools

Features

Burrs happen. Barriquan can handle them. We'd love to tell you how.

See it in action.

Application Examples

.jpg)

Pipe Ports/Holes : Surface

.jpg)

Pipe Ports/Holes : Underside

Casting Profiles and Flash Removal

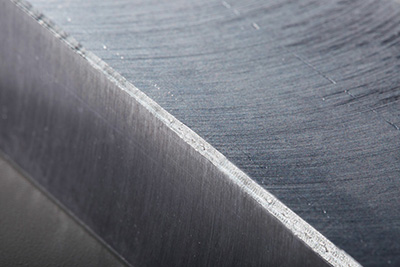

Edge : Before and After

Hole : Before and After